Essential Insights on Prefabricated Homes for Sale: Pricing, Benefits, and Key Factors to Consider

Outline:

– Market overview and the prefabrication process

– Pricing breakdown and affordability strategies

– Benefits that go beyond price

– Key factors to evaluate before purchasing

– How to locate, compare, and confidently choose listings

Understanding the Prefabrication Landscape and Why Listings Are Surging

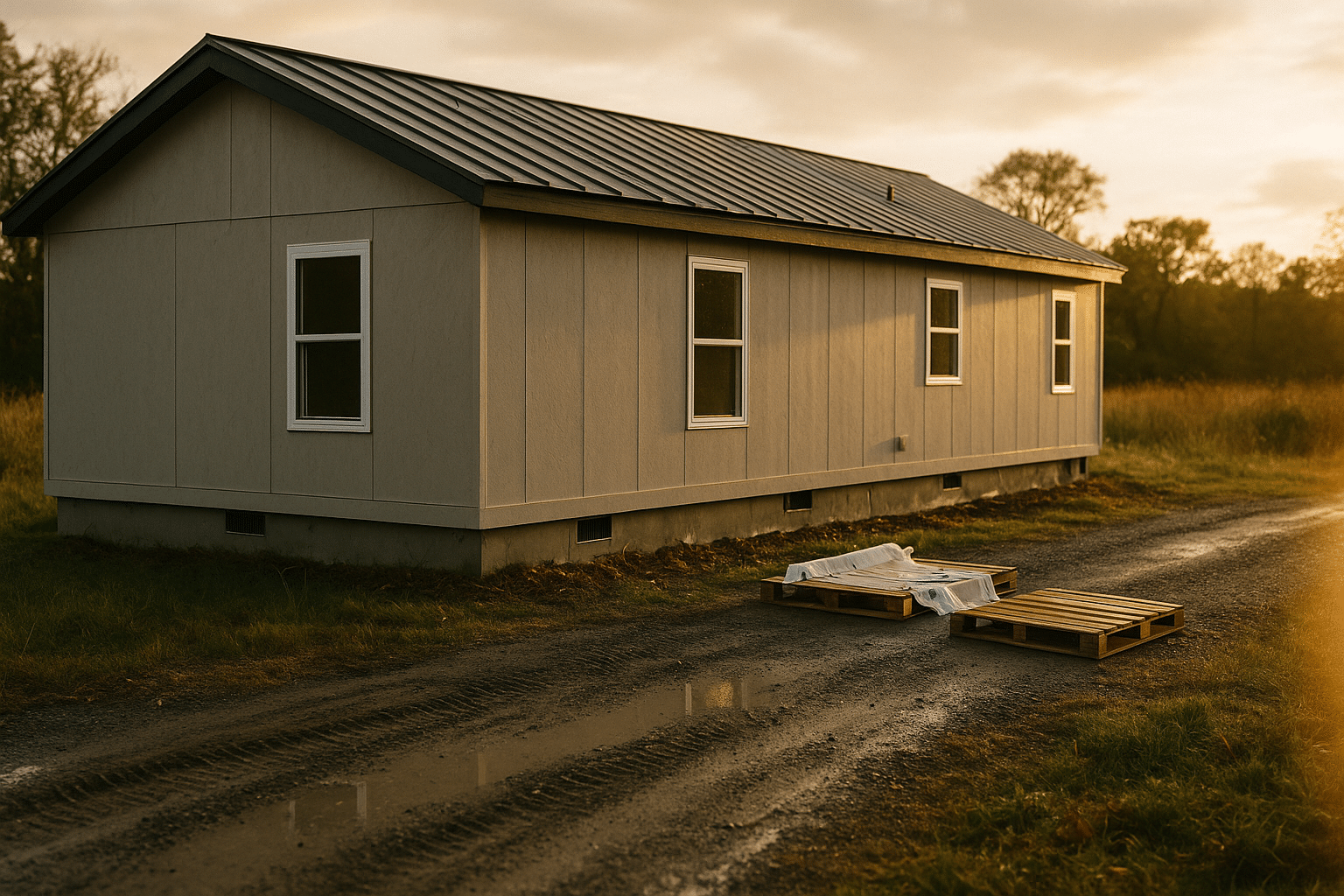

Prefabricated homes are built in factories in modules or panels and then transported for assembly on-site. This approach compresses schedules, reduces weather-related delays, and makes costs more predictable compared with many site-built projects. Broadly speaking, you will encounter several categories: modular (built to local residential codes and assembled on permanent foundations), panelized (wall and roof systems shipped flat for rapid framing), kit homes (precut materials for on-site assembly), and manufactured homes (built to a federal performance standard and delivered with transport frames). Each category has its own compliance rules, financing paths, and resale considerations, which is why comparing apples to apples matters when scanning listings.

Market interest has climbed as buyers look for quicker delivery, energy efficiency, and design flexibility. Urban infill parcels, suburban cul-de-sacs, and rural acreage can all be viable settings, provided local zoning and utility access align with the chosen model. Typical schedules run from several weeks for factory completion to a few months for full move-in, depending on permitting, foundation work, and utility tie-ins. Supply chains have also matured: factories optimize materials, and repetitive, climate-controlled workflows can boost quality consistency while limiting waste offcuts on-site.

Think of this overview as a compass for your search—Essential Insights on Prefabricated Homes for Sale: Pricing, Benefits, and Key Factors to Consider that ground you before you compare floor plans and finishes. As you read listings, get comfortable with the vocabulary on spec sheets: snow and wind load ratings, insulation values, roof assemblies, and the type of foundation anticipated. Keep a simple checklist nearby to track what each listing does—and does not—include at the advertised price. A little structure up front saves hours later and keeps expectations aligned with reality.

Quick prompts to guide early conversations:

– Ask which building code the home meets and how that affects financing and appraisal.

– Confirm what is included: foundation, crane set, delivery radius, and utility connections.

– Clarify typical lead times, change order policies, and any seasonal constraints for installation.

Pricing Deep Dive: What Drives Cost and How to Keep It Affordable

Pricing for prefabricated homes varies by region, build type, and the scope of site work. As broad, non-binding ranges, manufactured homes often start in the lower per-square-foot tiers; modular and panelized offerings can land in the mid to upper tiers; and highly customized or architecturally complex models approach or overlap conventional site-built pricing. Beyond the base price, your total budget will include land (if needed), foundation, transport and crane services, site prep and grading, permits, utility trenching and tie-ins, and post-set finishes such as decks, porches, or landscaping. Taxes, insurance, and contingency reserves complete the picture.

To orient expectations, consider a simple framework: base house cost, site and soft costs, and a 10–15% contingency. Site conditions can shift budgets dramatically; rocky soils, long driveways, narrow road access, or unusual wind or snow loads can add material upgrades, escorts for transport, or specialized cranes. Permitting services and inspections vary by jurisdiction, so request a schedule of fees early. Financing may hinge on the build category: permanent mortgages for modular on a fixed foundation tend to follow traditional pathways, while other categories may use chattel loans or specific programs tailored to factory-built housing.

Strategies that can keep numbers in line:

– Choose a standard plan with limited structural changes; reserve budget for finishes you touch daily.

– Opt for energy packages that cut utility bills without pushing into costly custom engineering.

– Sequence site work to avoid idle time fees for delivery crews and cranes.

When scanning Prefabricated Homes for Sale / affordable Prefabricated Homes for Sale / Top-rated Prefabricated Homes for Sale, look for clear inclusion lists and transparent allowances for items like appliances, HVAC, and floor coverings. Request written quotes for transport, set, and hookups rather than relying on rough estimates. Finally, phase your deposits and progress payments against documented milestones, helping protect cash flow and aligning incentives for timely completion.

Benefits That Reach Beyond the Price Tag

While cost and speed get headlines, the advantages of prefabricated homes extend into daily comfort, resilience, and long-term value. Factory conditions mean materials stay dry during assembly, which can support tighter building envelopes and consistent insulation installation. Precision cutting and repeatable processes reduce offcut waste compared with many traditional sites, and that can contribute to cleaner jobs, fewer bins hauled away, and less material shrinkage risk. Controlled environments also allow predictable schedules, which is a real benefit for buyers coordinating lease ends or school calendars.

Energy efficiency is a notable draw. Many models offer modern insulation assemblies, air sealing attention, and window packages that can moderate temperature swings and lower monthly bills. Over the life of the home, those operational savings may balance slightly higher upfront choices such as upgraded insulation or rooftop-ready framing for solar arrays. Durability features—like reinforced roof systems for local snow loads or impact-rated windows in coastal areas—can further tailor the home to the site’s demands. Buyers also appreciate that interior finishes arrive pre-installed or rapidly assembled, shrinking the time between delivery and move-in.

Practical benefits to keep in mind:

– Time certainty: factory slots and parallel site work compress overall timelines.

– Quality control: repetitive assembly lines enable consistent detailing and inspections.

– Reduced neighborhood disruption: fewer months of construction traffic and noise.

From a lifestyle perspective, thoughtful designs leverage open-plan cores, flexible bonus spaces, and storage-efficient nooks that make smaller footprints feel generous. Accessory dwelling units on multi-generational properties, compact cabins for rural retreats, or primary residences on infill lots all benefit from the same pre-planned coordination. Together, these advantages underscore why factory-built approaches have moved from niche to mainstream, offering a practical path to ownership without sacrificing comfort or style.

Key Factors to Consider Before You Commit

Successful purchases begin with due diligence. Start by confirming local zoning, setback requirements, allowable heights, and any design guidelines that influence roof pitch, cladding, or porch dimensions. Determine whether the home will be placed on a permanent foundation and which building code applies, because financing, insurance, and appraisal typically follow from that. Assess site logistics: road width for transport, overhead wires, turning radii for delivery trucks, and crane staging areas. Small constraints can become big change orders if discovered late.

Next, map the sequence from purchase agreement to certificate of occupancy. Request a draft timeline showing fabrication lead time, expected factory inspections, site preparation milestones, and utility coordination. Verify what warranties cover—structure, systems, finishes—and how warranty claims are handled for elements installed in the factory versus on-site. Ask for sample contracts and scrutinize terms for change order rates, storage fees if the site isn’t ready, and weather contingency language. Insurance and risk transfer during transport and set should be explicit, not assumed.

Here’s a useful mental checklist:

– Clarify who is the prime contractor for permits and inspections.

– Document the exact delivery route and any required escorts.

– Confirm final grading, drainage, and erosion controls to protect the foundation.

Finally, align expectations with your lifestyle goals. If you value rapid move-in, lock design choices early to minimize back-and-forth that can nudge lead times. If you prize customization, understand what the factory will modify versus what a local contractor should handle post-set. Keep these Essential Insights on Prefabricated Homes for Sale: Pricing, Benefits, and Key Factors to Consider at hand during walkthroughs and calls; they help you ask targeted questions, compare proposals fairly, and move forward with confidence grounded in facts rather than assumptions.

How to Find, Compare, and Choose Listings with Confidence

Start by curating a shortlist of listings that match your target size, code category, and timeline. Download spec sheets and place them side by side. Compare structural details (framing type, roof assemblies), thermal values, window and door specs, and included systems like HVAC and water heaters. Evaluate the clarity of inclusion and exclusion lists, because ambiguity often leads to later change orders. When you see models marketed as entry-level or highly rated, look for the underlying metrics—third-party inspections, code pathways, and performance features—rather than relying on headline tags alone.

Practical steps for a thorough search:

– Visit a completed home of the same model if possible; what you feel underfoot can’t be gleaned from a brochure.

– Request references from recent buyers and ask pointed questions about scheduling, communication, and punch-list closure.

– Inspect a module on delivery day if you can; note any transport scuffs, flashing details, and air-seal continuity at seams.

As you weigh Prefabricated Homes for Sale / affordable Prefabricated Homes for Sale / Top-rated Prefabricated Homes for Sale, track total ownership value, not just the sticker price. Energy use, anticipated maintenance, warranty strength, and potential incentives for efficient envelopes or renewable-ready wiring all feed the long-term equation. If two options are close on paper, consider site-fit elegance: does the roof pitch suit your region’s climate, does the plan align with sun angles for passive comfort, and will the cladding age well in your local conditions?

Conclusion: A Clear Path to a Smart Purchase

Prefabricated housing offers a practical mix of predictability, efficiency, and design flexibility. By pairing a transparent budget with thorough due diligence and a disciplined comparison process, you can move from browsing to closing with fewer surprises. Keep your notes organized, ask for documentation at every step, and pace decisions to protect timelines. With clarity on pricing, benefits, and the real-world factors that matter, you’ll be ready to secure a home that fits your needs today and adapts gracefully to tomorrow.